OK, pics are here, cell phone of course... so they suck.

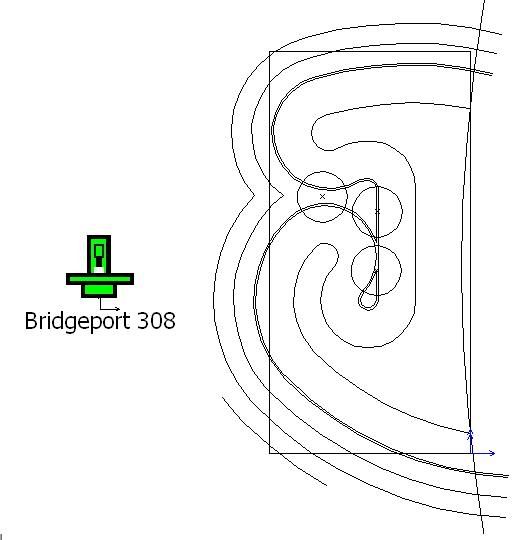

The fixture to hole the part, 2" x 2" x 8". Has a step milled on the end as well as the reverse contour and two mounting screw holes drilled and tapped.

Three relief holes drilled.

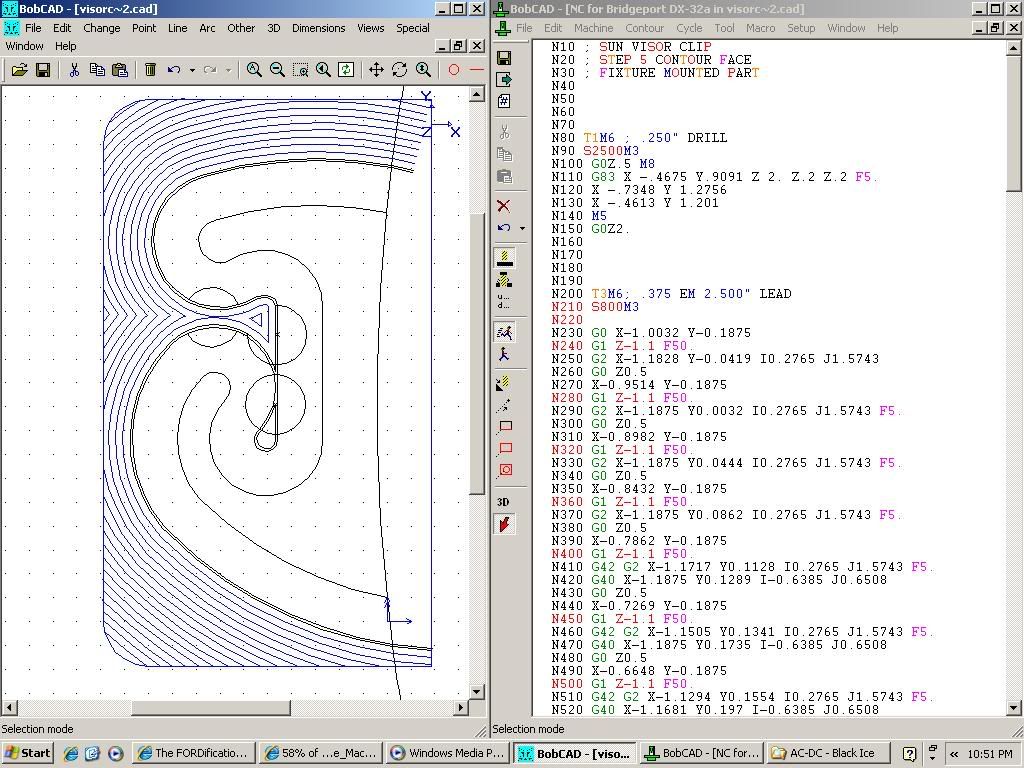

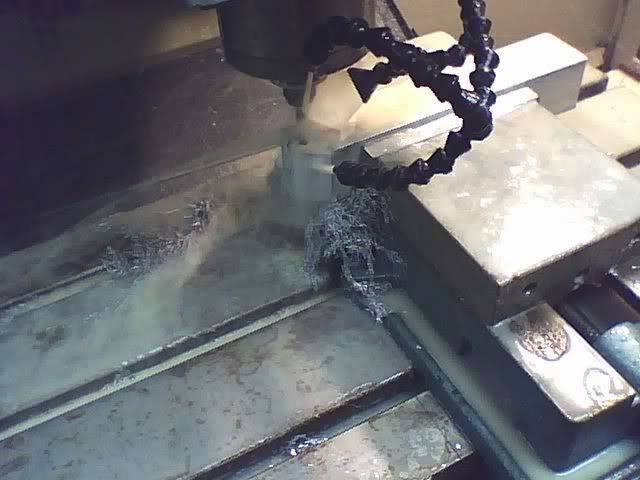

Milling the contour, about half way done here. Note I'm using a 2" lead 3/8" end mill to cut the whole thing in one pass.

Finished part. looks good on this side.

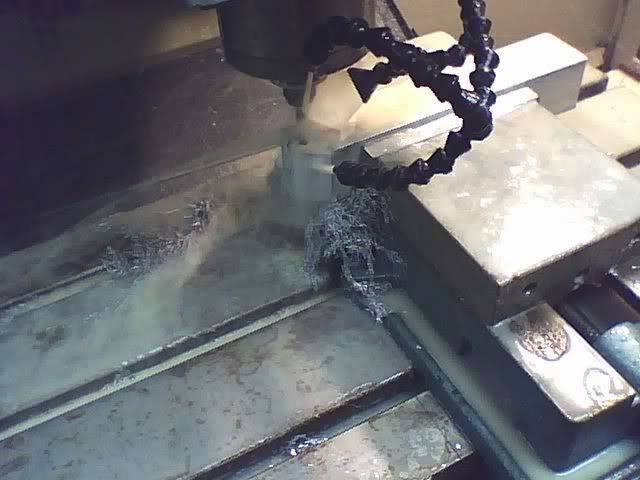

The good...

The bad... The long end mill deflected while cutting so I need to overcome this before making parts. The divit is where the spindle loaded up in the cut because there wasn't anywhere to put the extracted metal.

I'm not sure what I'm going to do. I could just have it redo the finish cut a couple times and hope it cleans it up or redo the program to cut it from both sides, but then I'll have some mismatch where the cuts meet. I'm not real happy with this part, but I expected some deflection.

It's raining out today so maybe I'll go down and play with it some more.

Jamie