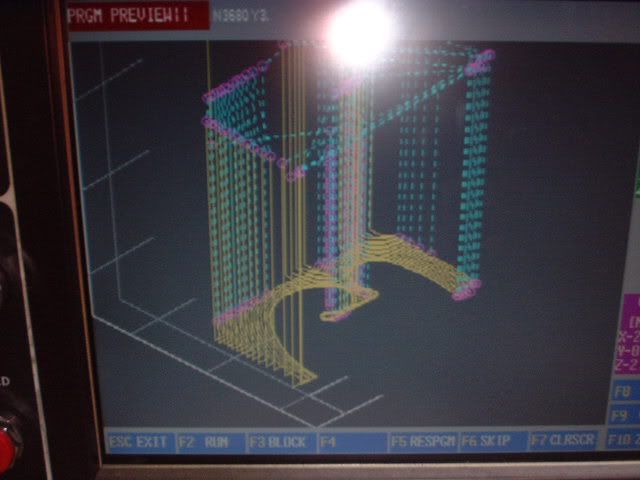

OK, been a while. I wasn't happy with how the parts were coming out with a long end mill so I redid the fixture and program to do the opposite side of two parts in one cut process, then flip the parts side for side and cut again. Taking .050" cuts at 25 inches per minute at 2500rpm worked out great. I did a loop function in the program to do the .050" depth cut 17 times.

I went ahead and wrote up the program to rough mill the top edge and then fly cut it smooth as well. So now I have to down to three setups and four cut processes. Still took 25 minutes per cut process today, it's two parts per hour. I may play with the depth of cut to speed it up some, but the parts are turning out really nice. As always, the decent camera has dead batteries so you get the fuzzy phone pics...

Two parts after the first step. The part on the left has the extra step to add the divider bar. The countersunk hole in the center of the fixture is for X0", Y1.00" position reference so I can resetup quickly once I put the fixture in the vise.

A fuzzy close up. Notice the mounting allen bolt holding the part to the fixture.

Six of the eight good parts I made today Took about eight hours to fine tune the program to get good parts that fit. The original program had the openings too tight for the visor tips to go in easily. Now they fit and hold a lot better.

Last two pics are todays bonus... Freebie '92 vintage Cub Cadet 1015 with a 32" deck and a 11hp briggs with no compression. Pulled the head and it was severely warped by the valves. The PO had added some dead soft aluminum to the head gasket to try and make it work. Used the fly cutter on the mill to tune it back into shape. Notice the head gasket...

And the freebie. I have $30 in two front tubes and a couple bucks in the head gasket. Thing even had decent gas in it. I need a key and to get the wiring working so it'll start off the key once the battery takes a charge.

OK, so tomorrow I need to run down to the farm and test fit the parts on some of the trucks down there. How ironic that my holes are drilled crooked from the factory...

Wish I would have noticed before I painted it and put the glass back in.

Jamie